Generations of Puget Sound mariners have trusted Mac's for premium boat cushions, boat interior upholstery and yacht upholstery.

We also design, fabricate and install custom helm seat covers, bow cushions, deck chair cushions, galley cushions, V-berth cushions, cabin cushions and deck cushions.

Drop by our showroom to view marine vinyls and fabric samples. See the latest patterns and colors from Sunbrella®, Spinneybeck, Duralee, Majilite, Robert Allen, Stamoid Marine, Ultrasuede, Kravet and Naugahyde®.

After viewing fabric samples, check out our boat cushion foams. They're available in a wide range of densities and sizes. We'll help you find the perfect combination of fabric and foam to meet your needs.

The vast array of vinyl samples in our showroom have one thing in common: they're all premium grade vinyls from established manufacturers such as Naugahyde® All American, Nauga Leather, Nauga Soft, Surfside, Spirit Millennium, Stratford, Chamea, Neochrome III, Universal and Twilight.

Mac's Upholstery is Puget Sound's premiere marine canvas and yacht upholstery shop. Customers line up for our cushions and upholstery because our craftsmen are so much better than anybody else. Here's an example.

Mac's Upholstery is Puget Sound's premiere marine canvas and yacht upholstery shop. Customers line up for our cushions and upholstery because our craftsmen are so much better than anybody else. Here's an example.

One of Seattle's top busines executives wanted new upholstery for the family's luxury yacht. We're used to big, demanding jobs like this, but the yacht's sun deck settee presented unusual challenges. It's quite a bit larger than a standard marine settee. Also, the serpentine shape and the choice of fabric required extensive customization.

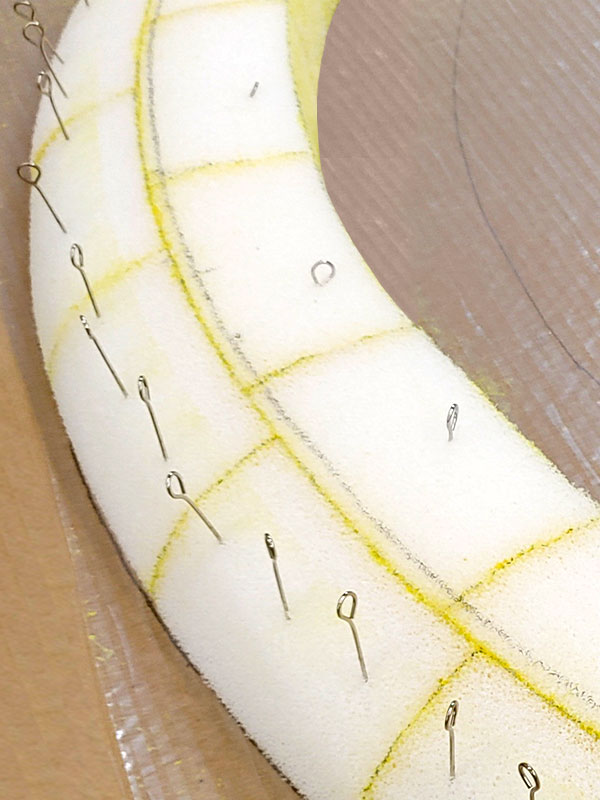

To begin with, the cushions needed to hug the sharply curved frame. Faceting the surface would've been the simple solution, but the owner wanted an elegant look. To achieve that, we cut dozens of slightly curved foam blocks, then joined them together to match the settee's graceful lines.

The owner selected a striped Sunbrella fabric for the cover. Matching a stripe pattern from one section of the settee to another can be challenging. It's doubly difficult when the sofa is curved. This is where subtle tricks of the trade and our decades of experience payoff. You can see the results. Impeccable.

Making something look good isn't good enough for our craftmen. It has to be durable and functional under any circumstance. The pitch and sway of open water can scatter cushions if they're not properly anchored. Snaps are one way to do it. In this instance, we shaped the cushions to slide perfectly in place, then fabricated a hidden mechanism to keep them there. They're anchored in place with Velcro strips hidden in strategic locations.

In the end, we were especially pleased with the way this custom marine settee turned out. More importantly, the customer loved it.

Wooden speedboats were the cat's meow back in the Roaring Twenties. Sadly, there aren't many of the original woodies left; they were hard to repair and maintain.

Wooden speedboats were the cat's meow back in the Roaring Twenties. Sadly, there aren't many of the original woodies left; they were hard to repair and maintain.

While it's not an original, this handmade replica is the spitting image of a Chris-Craft mahogany runabout from back in the day. It was manufactured by a Washington man from a set of authentic drawings he got his hands on. It took him ten years to do it. Can you believe this is the first boat he ever built?

While the owner did most of the work himself, he decided to leave the upholstery to the experts.

The cockpits in these old boats were designed to look like the inside of a sport car. Some of them even had foot pedals instead of throttle levers.

The seat cushions were also patterned after cars. We fabricated these seatbacks with Seaquest American Beauty vinyl using an automotive tuck a roll technique. The foam is two inch HR33. We used a stiffer three inch HR45 foam for the welted cushions. The vinyl trim around the edge of the cockpit and rear compartment dresses it up nicely.

What an amazing accomplishment for a first time boat builder! You'd have a hard time distinguishing this from the Real McCoy.

Custom Sectional for Salon

There's never enough storage space on a boat, so when the owners of a 62 foot Ocean Alexander needed a new settee, they wanted one with plenty of storage space. We recommended a custom settee with built-in storage compartments under the cushions. The owners liked the idea, so we went to work.

The owners wanted the "L" shaped settee to fit in a corner of their main salon. There was just enough space in between the bulkheads, a staircase and a heating duct to make it work. Because it was a snug fit, the measurements had to be right on the money. The dimensions were important for another reason, as well; fabricating the settee on board the boat was impractical, so we had to build something that would fit through the yacht's narrow passageways.

Custom Build "L" Settee (Before)

Upholstered "L" Settee in Salon (After)

Straight Grain Wood for Ribs

Frame Built in Sections

Built in Storage Compartments

Storage Compartments with Lids

Shaping Cushion Foam

Custom Settee Installed

We built the settee off-site in sections — three base components and four backrests — then assembled it in the salon.

The design included four easily accessible storage coffers under the seat cushions. They range in size from extra large to extra small. We used sturdy straight grain wood for the structural ribs and stylish birch plywood for the faces. Each section bolts into the one beside it. The joints are so seamless you'd never know it was built in sections.

Four inch HR45 foam was perfect for the seat cushions. We used a softer foam for the backrests. You'll notice the foam is slightly thicker in some places. The raised edges help cradle the occupant when seas are rough. The heavy duty polyester upholstry fabric (Crypton Charisma Linen) will stand up to almost anything.

Not all marine furniture requires indoor-outdoor upholstery fabric such as Sunbrella®. When a settee or chair is inside a yacht, standard upholstery fabric is usually fine. In this case, the owner wanted eight custom made 20 X 20 inch welted pillows for their salon. They selected blended indoor fabrics; a different one for each pillow.

Patterning Fabric

Fabric Pieces

Finished Pillow

Fabricating pillows is a straightforward process. You start with a pattern slightly larger than the pillow itself. It needs to be larger -- 26 X 26 inches for this one -- to accommodate the fiber stuffing. The welt, or bead as some call it, is assembled from a cord wrapped in fabric, usually the same fabric as the pillow. Welting doesn't make the pillow better, it's simply a style choice.

Dinette For Liveaboard Yacht

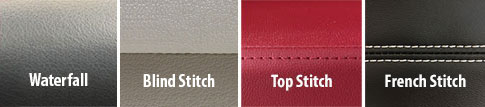

Here's a example of how something as subtle as upgrading a fabric and stitching pattern can revitalize a yacht interior.

These are dinette cushions from the galley of a 140 foot luxury liveaboard moored in Seattle. The owner wanted the six cushions and backrests from his U-shaped dinette reupholstered. He also needed new foam for the seat cushions.

Before & After Dinette Seatbacks

Top Stitched Old Cushion (left), French Stitched New Cushion (right)

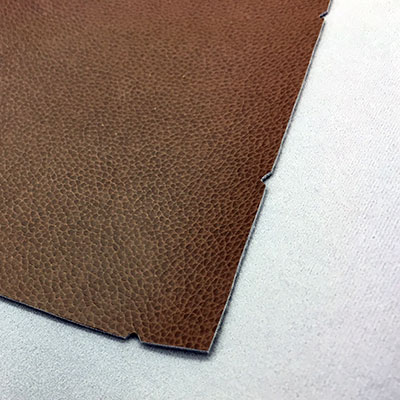

The yacht owner liked the pebbled texture of the old covers, but he wasn't crazy about the color, sort of a meh medium brown. After years of use, the old vinyl was also turning a little bit stiff.

The material we used to reupholster the dinette is a 100% polyurethane vinyl called Tolstoy Earth. It's also pebbled, but this vinyl is darker and more supple than the original. It's also stain repellent, easy to clean and extremely durable.

Alignment Notches

Temporary Scuff Protection

Pads and Seatback

"U" Shaped Dinette

When reupholstering a dinette such as this, we often replace the foam. As mentioned, the seat pads did need new foam, but the backrests were still in good shape. Instead of new foam, we used the existing foam for the back cushions. Reusing foam not only keeps costs down, it also minimizes waste.

Finished Dinette Installed in Yacht

The old cushions were a little lumpy when we began work. The upgraded vinyl and new foam helped smooth the padding, but the seams were still rough. We solved this problem by using a different stitching technique. The old covers were held together with a standard top stitch. Instead of a top stitch, we fabricated the new covers using a stylish French stitch. French stitching flattens the seams. It's not waterproof, but this is an indoor dinette, so that's not an issue.

Ultraleather™For Luxury Yacht

When the owners of the luxury yacht Southern Cross based near Santa Barbara decided to homeport a second yacht here in Puget Sound, they called Mac's Upholstery. They wanted to upgrade their interior in royal blue.

Since money was not an object, we upholstered a number of pieces on board the yacht including an eight piece bridge settee, a nine piece galley settee, the captain's bunk and a pair of helm chairs. Everything was reupholstered in Ultraleather®. While substantially more expensive than standard vinyl, Ultraleather®is perfect for a luxury yacht.

Reupholstered Helm Chair

Ultraleather® Fabric

Reupholstered Helm Chair

Ultraleather®has the rich look and supple feel of real leather, but it's easy to clean and a lot more durable. It comes in a range of colors and textures.

Before upholstering the helm chairs, we replaced the foam. It's important to use the right kind of foam, especially in a demanding marine environment. If boat or yacht seats are exposed to the elements we often recommend Dryfast™or EZ-Dri™Foam. They're large cell foams designed to shed water. In this case, large cell foam wasn't necessary – all the pieces we upholstered were intended for the bridge and salon.

Manufacturing a V berth cushion can be challenging. For one thing, the shape of a V berth varies from boat to boat. Cushion configuration, size and density also differ based on a boat owner's preferences.

Here's a seven piece V berth we built for a Sea Ray owner. As you can see, each cushion for this V berth is a different shape. They fit together like a jigsaw puzzle, so correctly sizing each cushion is critical.

Custom Fit V Berth

Crypton Fabric

Finest Craftsmanship

Selecting the right fabric is just as important. Many boat owners prefer Sunbrella®. Sunbrella's marine fabric is manufactured from solution-dyed acrylic, so it doesn't fade or change color in a demanding marine environment. It can be a little on the stiff side, however. The fabric we used for this V berth is much softer; 100% woven polyester with a Crypton finish. In addition to being soft, it's extremely durable. It's also stain, fade, abrasion, bacteria and odor resistant. In other words, perfect for this application.

Why We Don't Use Cheap Fabrics

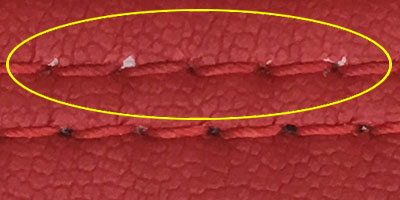

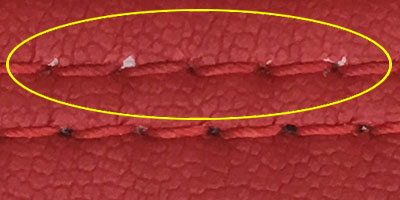

Customers sometime ask why we only use marine grade fabric when upholstering boat interiors and cushions. The pics below help illustrate why. The first one shows a standard grade red vinyl purchased by a customer to reupholster his boat cushions. The vinyl looks and feels great, but look what happened when we stitched through the material.

As you can see, the vinyl chipped around some of the thread holes. Adjusting thread tension didn't solve the problem. The vinyl face and thin backing on this fabric simply couldn't cut the mustard.

Fabric Tears

Flawless Stitching

The vinyl we use is more durable. Sewing this fabric into cushion covers was a breeze — the stitching turned out perfectly.

You'd think the better vinyl would cost more, but not in this case. Our superior quality marine grade vinyl turned out to be less expensive. So, be sure to contact us before buying lousy fabric from somebody else.

Sea-Doo, best known for its line of sporty personal watercraft, also manufactures speed boats. Speed boat seats take a lot of abuse during the summer. It's not uncommon for Sea-Doo seats to need repair every two or three years, especially if teenagers are bouncing around the boat.

We fabricate custom replacement seat covers for all speed boats, including Sea-Doos. But, if a boat owner likes the color scheme of their upholstery, it may be more cost effective to simply order an identical replacement seat cover kit.

In this instance, the seat cover stitching ripped, exposing the foam padding to destructive UV light. The boat owners put off repairs until the end of summer. By the time they brought the seats to us, the foam was pretty well shot. Instead of restitching a couple of seams, the cushions needed to be rebuilt and both seats needed new covers.

Fortunately, there was a Sea-Doo seat cover replacement kit available, which kept repair costs down. We rebuilt the damaged foam cushions, installed a set of identical covers and that was that; the seats were good as new.

Pleated Sun Pad For Seaquest

Here's a custom-designed sun pad we created for the bow of a 42 foot Sea Ray. It's fabricated from white and light grey Sequest Vinyl, a durable marine grade vinyl.

Here's a custom-designed sun pad we created for the bow of a 42 foot Sea Ray. It's fabricated from white and light grey Sequest Vinyl, a durable marine grade vinyl.

The pleated sun pad features a bolstered headrest adjacent to the windshield. The edges are also slightly raised.

There's a hatch built into the SeaRay's bow directly above the V berth. This ventilation hatch doubles as an emergency exit. Since the boat is a privately owned pleasure craft, there's no requirement to have a workable V berth hatch.

For safety reasons, we recommended keeping the hatch functional by building a rip-away cover into the sun pad. We used Velcro®so it easily pops open.

During the off season or when inclement weather strikes, it's easy to remove and store the three piece sun pad below deck or elsewhere.

Color-Matching Boat Cushions

Not all cushions in a pleasure craft wear at the same rate. If passengers prefer sitting in the stern, those seats wear faster than cushions elsewhere. Since there's no sense reupholstering all the seats when only some are damaged, the challenge becomes choosing a vinyl that matches the color and texture of the original fabric.

It's not as easy as you may think. Take the color white, for example. White comes in scores of shades and tones. Some are a little more "blue" than others. Some appear slightly warmer. It's sort of like the difference between fluorescent tubes and standard incandescent bulbs; the light from both are "white", but you definitely notice the difference.

Marine Grade Vinyl

Color Matched

Flawless Cushions

We carry hundreds of vinyls and acrylic-based marine grade fabrics. We'd be happy to suggest a color and pattern to reupholster a boat cushion, but ultimately the customer makes the choice. Whatever the choice may be, you can be sure that any boat cushion reupholstered by Mac's will be durable and flawless.

Here's an eight piece bow cushion we recently built for a 105 foot yacht. Bow cushions, like V berth cushions, can be challenging. Each bow tends to be a little bit different shape and angle. The striped fabric in this picture helps illustrate why correctly sizing the cushions is so important.

Notice the bottom cushions. Three on the inside are rectangular; the parallel stripes extend all the way down these cushions. At first glance, the outside cushions also appear retangular, but look closer and you'll notice how the outside stripe on these cushions don't go all the way. That's because they're slightly curved where they meet the gunwale. A less experienced upholstery trimmer might've missed this.

There's usually plenty of action onboard a ski boat; passengers running around the deck, hopping in and out of their seats. Upholstery can wear out fast. As you can see (left), this ski boat bucket seat was in desperate need of repair. And not just because of normal wear and tear. It ripped because the original vinyl was thin and stretched too tight.

Damaged Ski Boat Seat

Repaired Seat

The bolster arms were undamaged and the foam was still in good shape, so we focused our attention on the damaged insert. Instead of repairing it with the same substandard material, we used a stronger vinyl with a little bit of stretch. We also increased the seam allowance so there was more "give". After repairing the insert the seat was good as new.

How Not To Build Marine Cushions

Every once in a while we come across a real head scratcher; these boat cushions, for example. They're fabricated with EZ-Dri® foam. EZ-Dri is a stiff foam with large air pockets. Instead of absorbing water the way conventional cushions do, the air pockets in this foam are engineered to shed water.

Original Boat Cushion

Plastic Under The Cover

New Cover

Trouble is, the people who fabricated these boat cushions wrapped the EZ-Dri foam in waterproof plastic. Since EZ-Dri is designed to absorb and discharge water, covering it with plastic is counterproductive. Instead of draining water, the plastic cover created a perfect environment for mold and mildew.

And that's not the only thing wrong with these cushions. The white material covering the foam is Dacron®. Dacron is used to soften the crown of a cushion. These cushions were manufactured with the Dacronunderneaththe foam instead of on top. It doesn't do any good that way.

Before fabricating new covers, we cleaned and re-engineered the cushions so they worked right.

Generic boat cushions are easy to make. Fabricating premium quality, custom-fit boat cushions require the skills of a maritime upholstery craftsman. Here's an example of how pleasure boat cushions manufactured by Mac's are superior.

Generic boat cushions are easy to make. Fabricating premium quality, custom-fit boat cushions require the skills of a maritime upholstery craftsman. Here's an example of how pleasure boat cushions manufactured by Mac's are superior.

- We only use durable, marine grade vinyl

- Using two Velcro bands instead of one ensures cushions stay put even in rough seas

- Seams are meticulously stitched using heavy-duty thread

- To maximize air circulation, we drill a series of precision vent holes in the back of the cushion

- Gusseted zipper pockets keep the zipper slider in place

- Our premium quality upholstery and marine foams last years longer than standard foams

Recover Grady-White Cushions

If the owner of this Grady-White had waited any longer to fix the onboard cushions, it might have been too late. As you can see from the first two pics, the vinyl was already ripped to shreds and the foam was deteriorating.

Damaged Bench Seat

Damaged Boat Cushion

Recovered Boat Cushion

After repairing the damaged cushions with superior quality foam, we covered the cushions with marine-grade vinyl. Recreating the pleated backrest for the aft bench was a little tricky, but our craftsmen did a great job. They're the best in Seattle. As always, the reupholstered marine seats turned out great.

Here's a striking example of how new upholstery can transform a run-of-the-mill salon sette into something extraordinary.

Compare the original settee from a 42 foot Beneteau sailboat to the new one beside it. Look closer and you'll discover subtle design improvements, beginning with the cushions.

We improved the seating deck by building a foam ridge into the edge. The foam ridge not only cups a passenger snugly into the seat, it lifts their legs a couple of inches, reducing lumbar strain. We also contoured or angle-cut the back cushions for added confort.

Main Salon Starboard Sette, 42 Foot Beneteau Sailboat Before and After

Rather than snap fasteners, we used velcro. Velcro allows more flexibility in cushion placement. The notches you see in the cushions accommodate an arm rest and a mast cable. They're engineered to fit like a glove.

As always, we use only the finest marine-grade foams and fabrics. For this settee, the boat owner selected striking Mediterreanean colors from Sunbrella's marine fabric collection.

The reupholstered settee is snug, looks great, and fits the salon perfectly. And thanks to our design improvements and craftsmanship, it'll last for years.

Using Design To Fight Mold & Mildew

Seattle's damp climate encourages mold and mildew. When you factor in all the nooks and crannies found aboard boats, controlling mold can be a real challenge. Mold is not only unsightly and destructive, it's a health hazard.

Mold & Mildew Collect In Seams

Redesigning Cushion Cover

Sleek & Sanitary

If a boat owner can't keep a cushion dry, we recommend the next best thing – removing dark places where spores and grime collect.

One way to do that is by eliminating seams. In this case, we replace moldy tri-panel cushions with flat foam. Flat, symmetrical surfaces require fewer seams than something fancy. By removing seams, these freshly upholstered cushions not only look sleek, they now resist mold and mildew.

Mac's Upholstery is Puget Sound's premiere marine canvas and yacht upholstery shop. Customers line up for our cushions and upholstery because our craftsmen are so much better than anybody else. Here's an example.

Mac's Upholstery is Puget Sound's premiere marine canvas and yacht upholstery shop. Customers line up for our cushions and upholstery because our craftsmen are so much better than anybody else. Here's an example.

Strictly speaking, a Corded Seam or Welt is not a stitch, but it's a popular way to "dress-up" a seam. A welted edge starts with a strip of fabric wrapped around a cord. The finished cord is then sandwiched inside a blind stitch to enhance the cushion's appearance. Some prefer the look of a welt, but there's a downside. Unless you're careful, a welt will collect dirt. What's more, normal wear and tear — sliding back and forth across the cushion — can abrade the welt. It's not a big deal, just something to keep in mind if you prefer a welted edge.

Strictly speaking, a Corded Seam or Welt is not a stitch, but it's a popular way to "dress-up" a seam. A welted edge starts with a strip of fabric wrapped around a cord. The finished cord is then sandwiched inside a blind stitch to enhance the cushion's appearance. Some prefer the look of a welt, but there's a downside. Unless you're careful, a welt will collect dirt. What's more, normal wear and tear — sliding back and forth across the cushion — can abrade the welt. It's not a big deal, just something to keep in mind if you prefer a welted edge.

Give us a call or visit our shop if you need marine upholstery repaired. Mac's Upholstery patches holes and replaces zippers. We repair boat cushions, seat covers, bimini tops, helm seats, bow cushions, marine mattresses, cockpit covers, and mooring covers. We're also the place to go for custom boat seats, pontoon boat upholstery, commercial galley chairs, custom boat covers and settees.

Give us a call or visit our shop if you need marine upholstery repaired. Mac's Upholstery patches holes and replaces zippers. We repair boat cushions, seat covers, bimini tops, helm seats, bow cushions, marine mattresses, cockpit covers, and mooring covers. We're also the place to go for custom boat seats, pontoon boat upholstery, commercial galley chairs, custom boat covers and settees.

Wooden speedboats were the cat's meow back in the Roaring Twenties. Sadly, there aren't many of the original woodies left; they were hard to repair and maintain.

Wooden speedboats were the cat's meow back in the Roaring Twenties. Sadly, there aren't many of the original woodies left; they were hard to repair and maintain.

Here's a custom-designed sun pad we created for the bow of a 42 foot Sea Ray. It's fabricated from white and light grey Sequest Vinyl, a durable marine grade vinyl.

Here's a custom-designed sun pad we created for the bow of a 42 foot Sea Ray. It's fabricated from white and light grey Sequest Vinyl, a durable marine grade vinyl.

Generic boat cushions are easy to make. Fabricating premium quality, custom-fit boat cushions require the skills of a maritime upholstery craftsman. Here's an example of how pleasure boat cushions manufactured by Mac's are superior.

Generic boat cushions are easy to make. Fabricating premium quality, custom-fit boat cushions require the skills of a maritime upholstery craftsman. Here's an example of how pleasure boat cushions manufactured by Mac's are superior.