Seattle's fishing and crabbing fleets, commercial ships and military vessels count on Mac's Upholstery for durable marine-grade upholstery.

Trident Seafoods, Global Seafoods, O'Hara Corporation, Iquique US, Foss Maritime, Kirby Tugs, Clipper Seafoods, Aleutian Spray Fisheries, Coastal Villages, R & B Fisheries, Ocean Fresh Seafood, Premier Pacific Seafoods, Ocean Peace, Alaska Longlines, Alaska Leader and Blue North Fisheries are among our many commercial customers.

We also manufacture custom unpholstery for the US Navy and US Coast Guard, including the Coast Guard Cutter Healy.

Our work also includes large upholstery projects for Holland America Cruise Ships.

From bunks to galley seats, galley cushions, captain chairs, cabin upholstery, outdoor cushions, deck chairs, stateroom upholstery and curtains, we're Seattle's top commercial marine upholstery shop.

Our showroom stocks hundreds of commercial grade vinyl and marine fabric samples. We have dozens of foams to choose from. We'll help you find the perfect fabric and foam for the demanding marine environment whether it's the Bering Sea, the Gulf of Alaska, or the Inside Passage. Because we're close to the waterfront you can depend on us for quick custom changes, fittings and installation.

If you need your ship upholstery cleaned or repaired, give us a call or drop by our Ballard shop. Our boat cushion cleaning service is tops in town. Our canvas shop is conveniently located near the Ship Canal and Fishermen's Terminal. The canvas shop specializes in custom boat enclosures, custom yacht enclosures, Makrolon® enclosures, dodgers, boat covers and windows.

Galley Chairs for Trident Seafoods

The "Island Enterprise," is the crown jewel of Trident Seafood's fishing fleet, stretching an impressive 319 feet. As a top-tier catcher/processor, it navigates the challenging waters of the Bering Sea, harvesting and processing Alaska Pollock with precision during the late winter and early summer.

The "Island Enterprise," is the crown jewel of Trident Seafood's fishing fleet, stretching an impressive 319 feet. As a top-tier catcher/processor, it navigates the challenging waters of the Bering Sea, harvesting and processing Alaska Pollock with precision during the late winter and early summer.

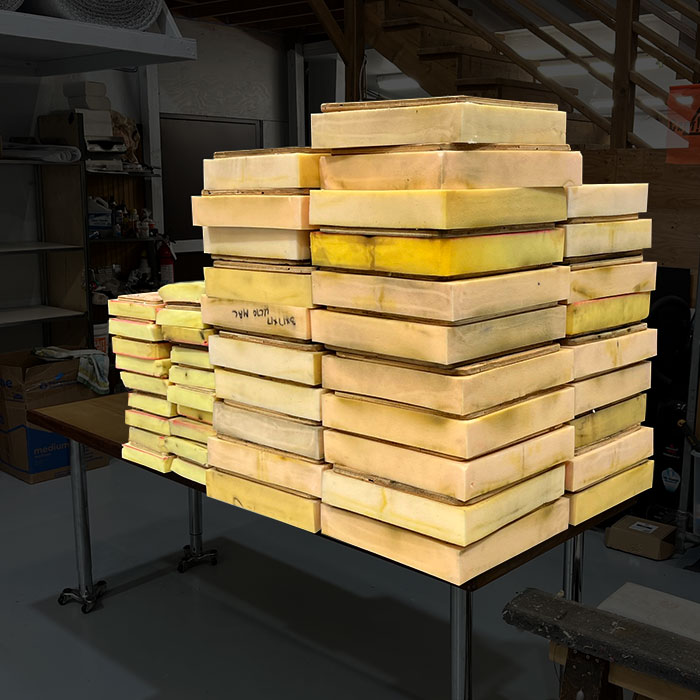

Two decades ago, we crafted bespoke swiveled galley chairs for this marine giant. Sturdy and resilient, our custom-manufactured chairs have proven to outlast their off-the-shelf counterparts. Yet, with the rigors of time and use, even the toughest seats require a touch-up every two to three years.

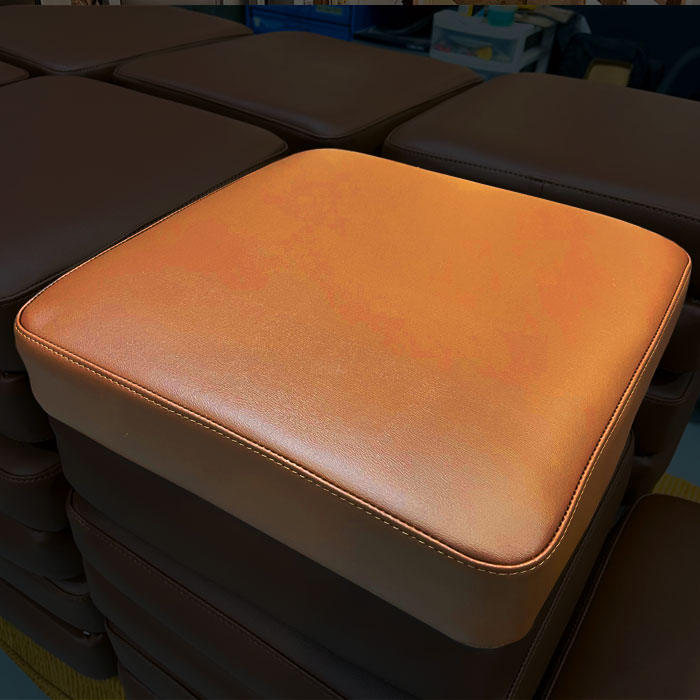

Enter Trident's recent refurbishment project: 39 swiveled galley chairs in need of a makeover. Our meticulous process began with a thorough cleaning and a fresh coat of paint for the frames. The heavy-duty swivels, the sole moving components, received specialized attention—either restoration or replacement, depending on their condition.

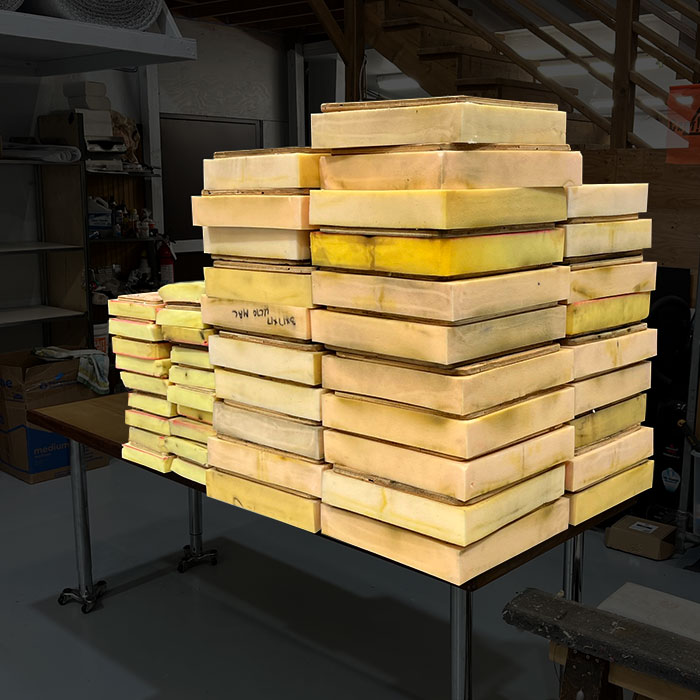

Foam is Still Good

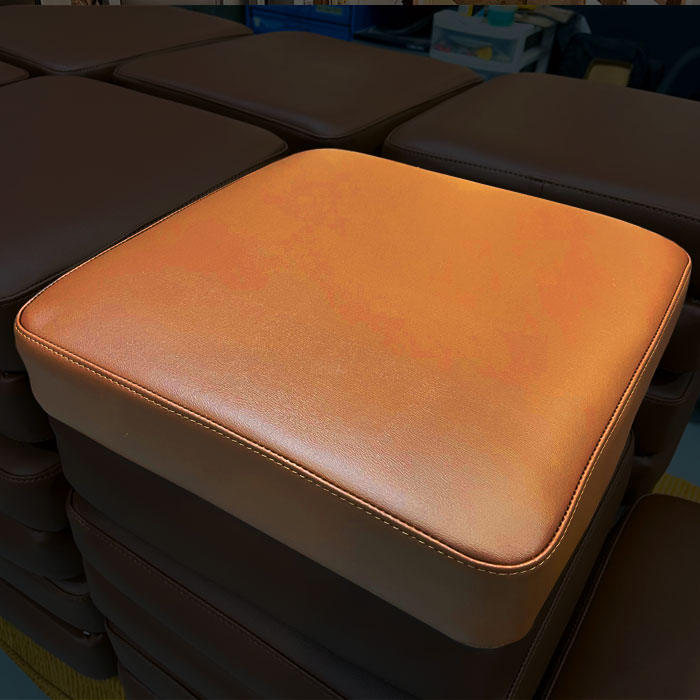

Recover Seat Bottoms

Marine Quality Vinyl

Recondition Swivels

Our commitment to quality shines through in the choice of the finest polyurethane for the foam cushions, ensuring longevity and reusability. However, the vinyl covers, subject to the brunt of wear, demanded a change. Trident, seeking a transformation from blue to brown, embraced the luxurious Olympus brown, a marine-grade vinyl of unparalleled excellence.

As the trusted partner of industry leader Trident Seafoods, we take pride in maintaining the impeccable condition of their upholstered chairs, benches, and settees. Upholding our reputation as the go-to marine upholstery experts, we not only meet but exceed expectations—delivering excellence that keeps Trident's marine assets in tip-top shape.

Modern helm chairs for commercial fishing vessels run the gamut from simple pedestals to injection-molded reclining chairs with multiple density foam packs, head rests, and self-leveling arms. There's nothing fancy about this one; it's an old school shell with a double-thick, removable seat pad. The captain needed it reupholstered before sailing to Alaska.

Helm Chair

Helm Chair Cushion & Armrest Repair

Reupholstered Helm Chair

Because they're so basic, upholstering one of these is pretty straightforward. We always use the best materials, in this case a marine grade burgundy vinyl. Foam densities vary based on how the cushion is being used. Most sailboat and pleasure craft cushions are manufactured using medium density foams, either HR33 or HR45 polyurethane. Cushions on a commercial fishing vessel require a denser foam, in this instance it's HR55.

While this style of helm chair is not modular, the seat pad is designed for easy on and off. If the cushion needs to be reupholstered or repaired, all you have to do is unscrew the pad from the base.

Remodeled Longliner Galley

At 161 feet from stem to stern, the F/V US Liberator is the largest freezer longliner in Aleutian Spray's fleet. It specializes in Pacific Cod from the sustainably managed and responsibly harvested longline bait fishery in the Bering Sea*.

At 161 feet from stem to stern, the F/V US Liberator is the largest freezer longliner in Aleutian Spray's fleet. It specializes in Pacific Cod from the sustainably managed and responsibly harvested longline bait fishery in the Bering Sea*.

The turbulent waters of the North Pacific can be tough on commercial fishing vessels. In between seasons, the US Liberator returns to its homeport in Seattle for supplies, crew changes and minor refits. Recently, the ship's galley was reconfigured. The project required brand new benches and cushions, so Aleutian Spray called us.

F/V US Liberator

Galley Seat Air Vents

Channel Marks

Rough Bench Cover

Finished Benchback

Finished Seat

Before fabricating cushions for the eight piece galley set, we drilled large holes into the seat decks. The strategically positioned holes allow air inside the seat cushions to vent when somebody sits down. This sort of passive "pressure release" mechanism is especially useful on ships like this with big body crews. Without vents, the cushions may trampoline and warp.

The top stitched seat cushions are fabricated from three inch semi-rigid polyurethane foam. The two inch seatback foam is quite a bit softer and wrapped in scrim fabric. The vinyl is a blue, marine grade Naugahyde. The vertical channels we stitched into the seatbacks are strictly decorative. Decorative stitching is fine for seatbacks, but we discourage channels in seat cushions because they collect crumbs and dirt. For the same reason, we recommend against welting galley cushions.

* According to NOAA Fisheries Fishwatch

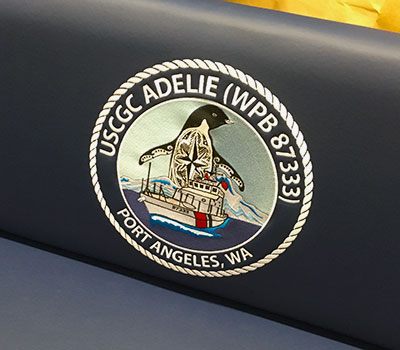

Galley Cushions for USCGC Adelie

If you've been to Port Angeles you may have seen the 87 foot USCGC Adelie moored off the sand spit. It's one of roughly 70 Marine Protector class cutters now in service across America. Similar Vessels are stationed in Bangor, Bellingham and Port Townsend. We do a lot of work for the military, so when the Adelie needed new galley seats they called us.

USCG Adelie

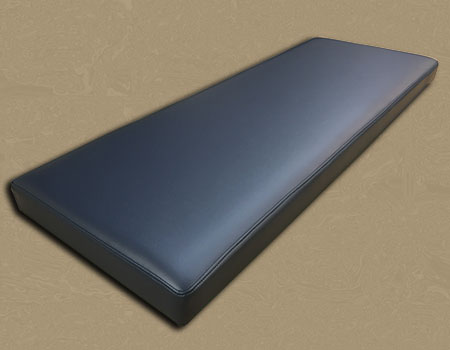

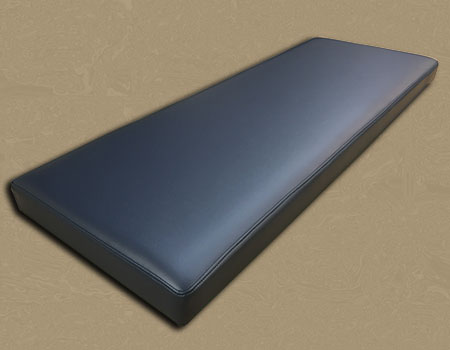

Galley Bench Seat

Galley Bench Seat

This is one of the benches we fabricated for the cutter. We used Olympus Majestic to complement the colors on the ship's emblem. Olympus is an extremely durable, marine grade vinyl. This easy to clean fabric is the perfect choice for a high traffic area like a galley. It's anti-microbial and stands up to the sun. It also resists stains and mildew.

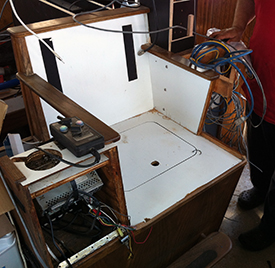

The F/V Theresa Marie recently used an extended break in Alaska's commercial fishery for a badly needed refit. Among other things, ship owners installed a brand new wheelhouse for better performance and comfort. They called us to upholster the new space. As always, we used a supple, durable marine grade vinyl to cover the galley benches and settee. The helm chair was a different story.

Recovered Llebroc Helm Chair

Reconfigured Bridge

Reupholstered Galley

Reupholstered Galley

The helm chair was brand new, but the captain didn't like how it felt. The vinyl cover was cheap and slippery. That's no small thing when you're riding monster waves in the Gulf of Alaska.

The captain wanted leather. And not just any leather; he wanted quality leather that would look good, feel good and last forever. He was willing to spend the money, so we recommended full grain leather normally used for motorcycle chaps. This sort of leather is an eighth of an inch thick and tough as nails. It was exactly what he wanted. It should make for more comfortable, if not smoother sailing.

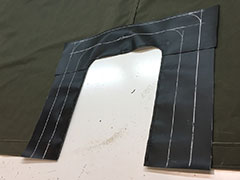

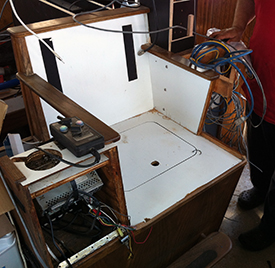

Almost any kind of ship repair requires a portable welding capability. A dependable welding tent is just as important as thick leather gloves and a good helmet. When a tent breaks down or tears apart stray sparks can escape the containment area and start a fire.

This beat-up welding tent (first two pics) was so far gone that it couldn't even be patched effectively. Defintely time for a new one.

Damaged Welding Tent

Old Welding Tent

Rebuilt Welding Tent

New Welding Tent

The owner wanted the same size tent, but without the plastic window. There were a few other tweaks, as well. To keep the dimensions identical, we used the old tent as a template. We fabricated the new tent using army green "duck" cloth, more commonly called canvas. Before installing new grommets we double-stitched the seams for additional durability.

The welder could have purchased a brand new tent, but this way he got exactly what he wanted. And it should last longer that something you'd buy off the shelf.

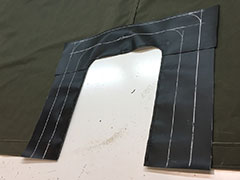

Mattress Designed to Fit Hull

The last thing you want at the end of an exhausting day on deck is to collapse on a mattress that slides all over the place because it doesn't fit. When a bunk abutts a hull the mattress needs to be beveled to fit correctly, especially if the mattress is in the bow. Structural ribs and conduits complicate matters.

Cut To Fit Hull

Measuring Fabric

Here's an example of a large mattress we recently built for a fishing vessel. Instead of cutting the foam based on the bunk dimensions we went to the ship and hand patterned the space. Conduits and structural supports don't always travel in straight lines so it's important to see the actual space beforehand.

Even after collecting an accurate pattern, properly cutting the foam isn't easy. There are at least three different angles in this odd shaped mattress. Each one has to be measured, cut and fitted for fabric.

When done properly, the mattress fits like a glove and stays in place even in rough seas.

This is the biggest, baddest, most extravagent dog bed we've ever seen, let alone made. It's one foot, by two feet, by five feet of the finest cushion foam money can buy. And even though it's mostly air, this colossal chunk of pink polyurethane weighs nearly thirty pounds.

Chunk o' Foam

Vinyl Fabric

Applying Cover

Zipper Pocket

We made it for a commercial fisherman who wanted something to fill a space on the bridge that doubled as a dog bed. Funny thing is, his dog is nothing but a bug-eyed little Chihuahua! Can you picture this tiny dog on this colossal bed? Okay, we made-up the part about the Chihuahua, but the fisherman did actually buy this for his dog. And it wasn't cheap. What have you done for your little buddy today?

You don't find too many identical bunks on a fishing vessel. The reason is simple; a ship's hull design usually determines the shape and placement of sleeping quarters. That means each bunk is usually a little bit different. Here's an example of why it's important to measure each individual bunk before fabricating a mattress for it.

A fishing vessel recently pulled into port needing new mattresses. One of its crew members measured a couple of bunks then took those measurements to another upholstery shop in town. The shop manufactured mattresses for the entire ship based on those dimensions.

Mattress Too Large For Bunk

Resizing For Proper Fit

Stiff Rebond Foam

Mattress After Resizing

Unfortunately, the measurements were only correct for two bunks. The other ones were way off.

Realizing their mistake, the ship delivered the oversize mattresses to Mac's Upholstery for refitting. Most of them had to be trimmed, in some cases quite a bit. Not only did the ship have to pay to have the mattresses resized, it shelled-out way too much money for the original foam. And foam isn't cheap!

Now you see why we insist on measuring each and every bunk before fabricating a ship's mattresses.

Mattresses For F/V Blue Attu

When Seattle's commercial fishing fleet needs mattresses, they call Mac's Upholstery. We custom-manufacture polyurethane foam mattresses and mattress covers for fishing vessels, processing ships, crabbing boats, and military watercraft. Foam mattresses for ships tend to be uniform in size, but bunks adjacent to hulls often require beveled edges. It's important to get the shape right or the mattress may not stay put!

We recently manufactured these 23 marine mattresses for the F/V Blue Attu, berthed near the Ballard Locks.

Because we use high quality polyurethane and memory foam, our custom-manufactured mattresses last a long time. In addition to being durable, they're comfortable. Foam is available in a wide range of depths and densities, so mattresses can be engineered to maximize individual comfort.

New Seat Covers & Marine Mattress for F/V Noble Hunter

Fabricating new seat covers and a helm chair for Seattle-based F/V Noble Hunter was pretty straightforward. We used brown marine-grade vinyl for the seat cushions and Duramax cloth — a much more comfortable fabric — for the galley seat back. It would've been nice to use Duramax for the entire project, but vinyl is tougher and a lot easier to clean.

Sleeping Berth

Helm Chair

Galley Seat & Seat Back

Galley Seat & Seat Back

The tricky part was building a mattress for the sleeping berth. As you can see (upper left), the berth is oddly shaped and notched in three places. The captain wanted a tight-fitting mattress cover made from Sunbrella fabric. Sunbrella is durable, stain-resistant and it doesn't stretch.

In this case one of its advantages is working against us — wrapping a stiff fabric tightly around a piece of foam results in a trampoline effect. After explaining this, the captain approved a slightly looser fit. We adjusted the fit and the mattress turned out great — the cover looked crisp, but yielded just enough for comfort.

Swivel Chairs for F/V Unimak

Galley swivel chairs are pretty common on large fishing vessels such as Seattle-based F/V Unimak. This sort of chair provides a nice range of motion, but remains anchored to the deck even in rough seas. Since the galley is often the "social hub" of a fishing vessel, swivel chairs get a lot of use. Every two or three years they need to be recovered.

We recommended recovering these chairs with a black polyester-backed PVC vinyl. This fabric not only looks great, its durability is rated at 1.5 million double rubs — almost indestructible.

Swivel Chair Cover Panel

"Christmas Tree" Fastener

Fastener Base Visible

Fastener Base After Routing

Trim Ring

Trim Ring Hides Swivel

Reupholstered Chair Back

Reupholstered Chair Seat

We not only recover swivel galley chairs, we manufacture them. There are some nice design features built into these galley chairs. Instead of bolting a generic cushion onto a naked vertical support bar, upholstered cover panels hide the hardware. So-called "Christmas tree" fasteners anchor the cover panels in place. The fastener bases slide into routed notches, making them invisible from the outside. Trim rings anchored under each seat cushion protect the swivel mechanism.

If you're interested in swivel galley chairs, give us a call. Prices start at $365.

A hearty meal in a warm galley does a lot to boost morale, especially for an exhausted crew battling the North Pacific. Comfortable galley seating is just as important as good food. In most cases, a plush, tufted booth is a lot more inviting than a row of single barstool-style seats.

Trident Seafoods recently delivered a galley booth in need of new upholstery. The old cover was poorly installed and – in our opinion – too slippery for stable seating in rough seas. We convinced the company to upgrade to a durable vinyl with a "tackier" finish. We also changed the tufting to improve performance.

Galley Bench Before Reupholstery

Sloppy Tufting

Designing New Tufting Pattern

Contoured Stitch

Stitched Replacement Cover

Flip Side

Ready For Buttons

Galley Bench After Reupholstery

The old tufting was pleated – extra material surrounding the buttons was folded and tucked instead of trimmed. In addition to looking sloppy, this style of tufting makes cleaning difficult – dirt and debris inevitably collect in the folds.

Our solution to this problem required a few additional steps. Instead of folding the excess fabric, we stitched rounded diamond contours in the vinyl, trimmed the extra material, then finessed the fit. As you can see from the final two pics, the reupholstered booth seat looks a lot better. It will also be much easier to clean.

Galley Seats For Trident Seafoods

Even when a commercial fishing vessel is out to sea, they count on Mac's to manufacture and deliver superior quality products. For example, Trident Seafood's Kodiak Enterprise recently needed new galley seat covers, so they contacted Mac's Upholstery. Trouble is, the ship was on assignment in Alaska and wasn't scheduled into port anytime soon. Instead of waiting weeks, or even months, the company stripped the old galley seats from the ship in Alaska and sent them to our shop in Seattle.

We recovered the seats, then shipped them back to Alaska.

Kodiak Enterprise

Fabricating Seat Covers

Superior Craftsmanship

Ready For Shipment To Alaska

Ship owners outside of the Seattle area often ask us to manufacture custom marine upholstery. To do the job correctly, we need the seat or the seat foam in our shop. Sending us a seat's dimensions isn't good enough. Having the cushion "in hand" is the only way to guarantee a perfect fit.

These five skiff seats had been torn to shreds during intensive Coast Guard training classes. We could have recovered them with a similar vinyl, but six months later they'd end up back in the repair shop.

When standard vinyl isn't tough enough, we recommend a specially manufactured super-tough, double-dog-dare vinyl used for truck tarps, pool covers, container booms and marine hatch covers. You'd be hard pressed to find a more durable fabric. This stuff has been put to the test time and time again.

Prepping Skiff Seats For New Covers |

Applying Tougher Vinyl |

Ready For Coast Guard Training |

Before recovering the skiff seats, we strip the old vinyl and dry the cushions for several days. There's not a lot of stretch in the new fabric, so it's important to pattern and cut with care. The application process is pretty straightforward – fabricate the covers using the strongest available thread, then snap the cushions in place with heavy duty, stainless steel staples.

The new vinyl won't last forever, but it'll perform a lot better than the old stuff.

Galley Chairs For Aleutian Falcon

Mac's Upholstery is the leader in commercial marine upholstery. Seattle's fishing and crabbing fleets trust Mac's because we manufacture durable, quality marine upholstery. Since serving commercial fishers and crabbers is our top priority, we finish every job on time -- before the fleet sails. We never miss a deadline!

These custom-made galley chairs were fabricated and delivered to the Aleutian Falcon with plenty of time to spare.

These galley chairs are made from scratch. We special-order the steel frames and swivel mechanisms, then custom-cut the seats and seat backs. After adding the foam, each is upholstered in a durable, marine-friendly vinyl. These galley chairs are covered in Chestnut Naugahyde -- a tough, American-made vinyl that meets or exceeds standards set by major regulatory agencies, including the Port Authority of New York/New Jersey and California.

Helm Chair and Galley Seats

Seattle's commercial fishing fleet counts on Mac's to deliver quality work on time.

When it's not anchored at Fishermen's Terminal, the Hawk works as a fishing vessel and tender in Alaskan waters. During a recent fitting, the captain invested in some badly needed cushions for the galley and helm chair. The custom-made cushions required quite a bit of work to properly fit both the chair and benches.

The Hawk's Galley

New Upholstery Foam

Marine-Grade Fabric

Notched Cushion

Helm Chair

Boat Seat Upholstery

The galley cushions were fashioned to provide easy access to hidden storage bins beneath the seat. The blue vinyl fabric is tough and easy to clean. The helm cushions were covered in a soft, but durable tweed. They not only had to be the correct size and depth, they needed notches on both sides to fit properly. As you can see, all the cushions turned out great!

Choosing The Right Fabric

Seats on commercial fishing vessels are put to the test on a daily basis. Damaged cushions are often held together with little more than a few strips of tattered duct tape. When Seattle's fishing vessels return to port they call Mac's to repair and reupholster everything from bunks to galley chairs. Before doing the work, we make sure the fabric we use is right for the job.

Durable Olympic Vinyl

Upholstered Seat Cushions

Recovered Chair

Welted Cushion Seams

Here's a great example of an excellent, marine-grade fabric ideal for the demands of a working crew. This is a slightly textured, satin finish black vinyl manufactured by Olympus. In addition to looking great, this vinyl is easy to work with. It's also sturdy -- it's rated 1.5 million double rubs -- and it resists damage from most chemicals found in a marine environment.

The "Island Enterprise," is the crown jewel of Trident Seafood's fishing fleet, stretching an impressive 319 feet. As a top-tier catcher/processor, it navigates the challenging waters of the Bering Sea, harvesting and processing Alaska Pollock with precision during the late winter and early summer.

The "Island Enterprise," is the crown jewel of Trident Seafood's fishing fleet, stretching an impressive 319 feet. As a top-tier catcher/processor, it navigates the challenging waters of the Bering Sea, harvesting and processing Alaska Pollock with precision during the late winter and early summer.

USCGC HEALY

USCGC HEALY

US NAVY RTSC

US NAVY RTSC

At 161 feet from stem to stern, the F/V US Liberator is the largest freezer longliner in Aleutian Spray's fleet. It specializes in Pacific Cod from the sustainably managed and responsibly harvested longline bait fishery in the Bering Sea*.

At 161 feet from stem to stern, the F/V US Liberator is the largest freezer longliner in Aleutian Spray's fleet. It specializes in Pacific Cod from the sustainably managed and responsibly harvested longline bait fishery in the Bering Sea*.